Method of extinguishing fire for burning forests using powders Class A

1. It is used the floor landing equipment ( IL-76, AN-12, AN-30, AN-74) for non-parachute dropping of humanitarian aid. It is development of the company “Advanced Technology and Service” for WFP (World Food Program). See the website: www.drop-rus.ru. Dropping technology was tested by more than 180 thousand tons of cargo dropped in Africa (1998-2012, Sudan, Kenya, Uganda, Central African Republic) with IL-76, AN-12;

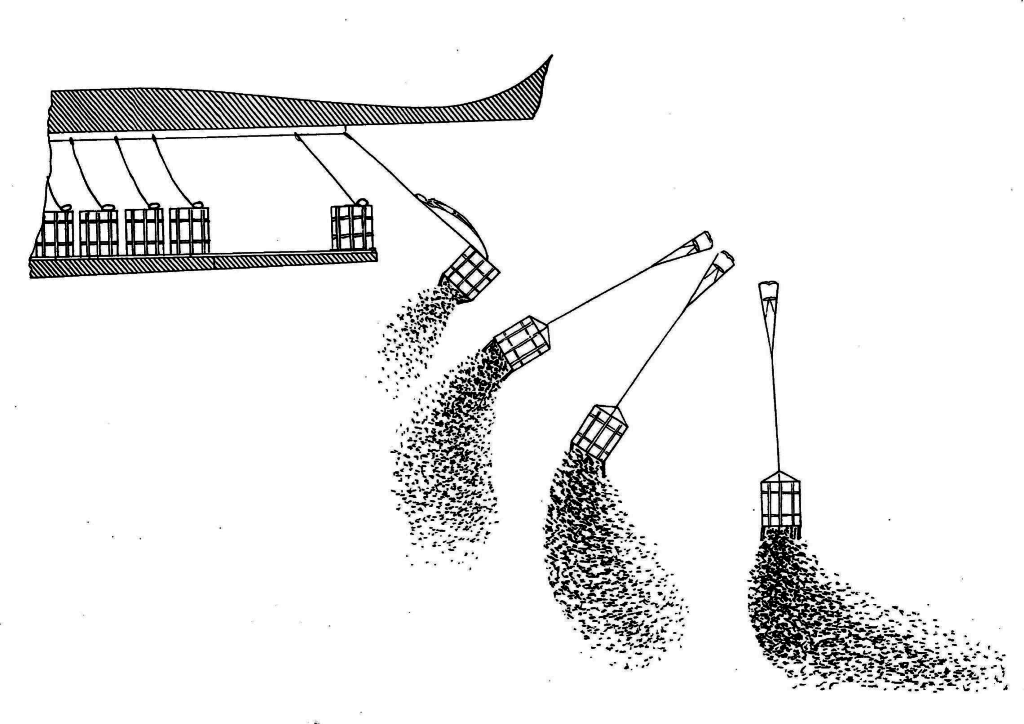

2. Dropping is carried out in one flow alternately from each side – 4 pallet from the right and then 4 pallet from the left. The interval of drop may be 0.3 to 1 sec (23-77 m).

3. Dropping of all cargo (26-28 pallets) from the plane is carried out in three waves.

4. When loaded on one pallet 1500 kg (total loading of the aircraft 39000 kg) the spot on the earth’s surface is approximately 50×12 m (about 600 square meter) at flight speed 280-300 km/h with height of 150-200 m.

Thus, the total length of firefighting strip for one flight of aircraft will be 1400 m with width about 12 meters (approximate area 16,800 sq. M). This provides an average density 2.5 kg of powder per sq.m.

Fig. 1. The scheme to drop powder

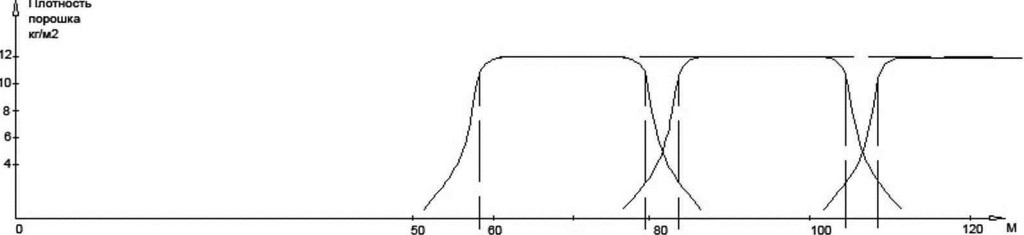

Moment of separation of boxes from the plane dt=1s 23 m (10 m wide) with density 12 kg/m²

Fig. 2. Timing of powder spraying

If necessary, the average density of the powder can be changed by changing the interval of separating the pallet from the aircraft and the speed of drop.

We have the price of extinguishing powder 30-35 rubles per kg.

Powder container is designed for landing and evenly spilling of extinguishing powder at parachute firefighting.

The container consists of the following main parts:

1. External box;

2. Discharge cassette;

3. Suspension system with elements of gain;

4. Supporting parachute system.

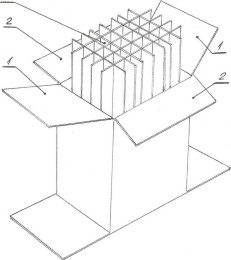

The outer box (Figure 3, Pos.1, 2) is designed to accommodate the powder. The box is made of corrugated cardboard brand P-32 – P-35 Profile SV or SE and has assembled dimensions W1000xL1400xH1300 mm, which provides accommodation for at least 1250 kg extinguishing powder Class A.

It can increase the load of boxes up to 1500 kg.

Fig. 3. The outer box with discharge cassette:

1 – transverse wall boxes; 2 – longitudinal duct wall; 3 – discharge cassette.

Discharge cassette (Fig. 3. Pos.3.) is designed to provide evenly spray of powder during drop of container. It is made of three-ply corrugated cardboard sheet brand T-21-T-24.It consists of seven narrow, and four broad combs. The assembled structure is formed by 40 cell tubes.

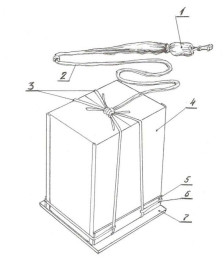

Suspension system is designed for fixing container to supporting parachute system. It is made of ribbon LTPE-30-1000, two links of length 6.0 m, as well as two limiting links of ribbon LTKP-26-450 1.9 m in length. To distribute the load on bottom of the outer box it comes with two angled element of gain made of three-layer plywood and corrugated cardboard.

Supporting parachute system is designed to ensure correct positioning of the container during the drop. It consists of a parachute with area 1,5m², extension link and parachute camera. The parachute is used from decommissioned systems such as D-6, D-5 (stabilizing).

Fig. 4. Final assembly of powder fire extinguishing systems:

1 – supporting parachute system; 2 – link of supporting parachute system; 3 – ribbon of suspension; 4 – box with the powder; 5 – angular element of gain; 6 – limiting unit; 7 – platform.

The volume of powder on one platform _________________ 1000x1400x1300 = 1.82 m³

The mass of powder on one platform ___________________ 1,82×0,7 = 1274 kg

The mass of a single platform with a box (without powder) __ 40 + 5 kg

Flight weight of one platform with powder ________________ 1172 kg

Loading of IL-76 per one drop of 26 platforms _____________ 30,472 kg

28 platforms _______________________________________ 32,816 kg